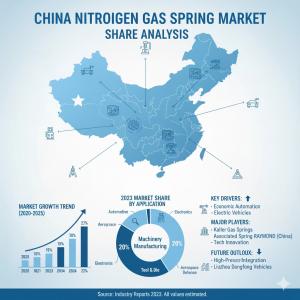

Shift, grow from USD 259.2 Million to USD 591.4 Million at 8.6% CAGR in China Nitrogen Gas Springs Market Share Analysis

Precision stamping, high-pressure performance, and automotive adoption driving industrial momentum

NEWARK, DE, UNITED STATES, November 6, 2025 /EINPresswire.com/ -- The China Nitrogen Gas Springs Market Share Analysis is projected to expand from USD 259.2 million in 2025 to USD 591.4 million by 2035, achieving a robust CAGR of 8.6%. This growth is propelled by automotive stamping, aerospace applications, and industrial machinery that rely on durable, high-force nitrogen gas springs. Rising demand for predictable force, long service life, and minimal maintenance is compelling manufacturers and industrial integrators to adopt high-pressure and compact gas spring solutions.

The market’s acceleration is fueled by industries seeking repeatable motion, consistent output, and operational reliability under high pressure. Automotive, aerospace, electronics, and heavy machinery sectors increasingly use nitrogen gas springs to meet modern manufacturing standards. OEMs and integrators are upgrading systems to include springs that improve cycle times, reduce operational variation, and support precision stamping and forming processes.

Market context

Nitrogen gas springs have evolved beyond simple lift-and-support functions. Today, they are integral to precision stamping, die-forming, and industrial load control, where uniform force and repeatable performance are essential. In automotive production, high-pressure springs help in forming lightweight structural parts, supporting hoods, trunks, and adjustable seating assemblies. Aerospace and heavy machinery applications demand springs with long service life, high durability, and resistance to corrosion, while electronics and medical sectors require compact, high-performance solutions that optimize space and maintain predictable output.

Buyers, installers, and OEM programs are actively planning upgrades to high-pressure, durable, and customizable springs, creating a repeatable adoption cycle. The integration of automation, energy efficiency, and regulatory compliance positions nitrogen gas springs as indispensable for industrial operators looking to improve throughput while reducing downtime.

Get access to comprehensive data tables and detailed market insights — request your sample report today!

https://www.futuremarketinsights.com/reports/sample/rep-gb-20533

Fast facts

• Market size 2025: USD 259.2M

• Market size 2035: USD 591.4M

• CAGR 2025–2035: 8.6%

• Leading product: Standard gas springs 46.8% share

• Secondary product: Compact gas springs 35% share

• Top application: Automotive stamping 32.7% share

• Industrial machinery share: Data not disclosed in client file

• Aerospace & defense share: Data not disclosed in client file

• Top players: Changzhou Longxiang, Maanshan Vantrans, Wuxi Jinrong 22% share

• Other regional players: Qingdao Sanyite, Foshan Owenlan, smaller tier-3 manufacturers

• Dominant sales channel: Direct sales to industrial clients

• High-growth regions: China, Japan, India, US, Germany

Product taxonomy highlights

• Standard gas springs – Versatile for automotive hoods, trunk lids, seating, and industrial equipment

• Compact gas springs – Space-saving, ideal for electronics, office furniture, and lightweight automotive components

• Low-force springs (<500 N) – Used in seating, light automotive components, and medical devices

• Medium-force springs (500–5,000 N) – Industrial machinery, stamping, and automotive systems

• High-pressure springs – High-load stamping, die-forming, and aerospace applications requiring consistent output

What is winning and why

Nitrogen gas springs are driving adoption because they combine controlled motion, predictable force, and heat-resistant performance. Industrial buyers prioritize springs that reduce downtime, improve reliability, and maintain safety in high-pressure environments.

• Power adders – High-force springs for automotive stamping, ensuring uniform material forming

• Chassis and brakes – Springs supporting heavy industrial loads with repeatable performance

• Digital tuning and calibration – Enables precise adjustment for high-performance industrial and automotive processes

Where to play

The market thrives in direct sales channels to OEMs and industrial integrators, while distributors and wholesalers supplement regional networks. Localized manufacturing hubs accelerate delivery, reduce cost, and support rapid adoption in high-demand regions.

• China – 5.4% CAGR – Expanding automotive, aerospace, and electronics manufacturing sectors

• Japan – 4.2% CAGR – High-precision industrial equipment and aerospace components

• India – 7.4% CAGR – Rapidly growing automotive and electronics industries; cost-sensitive adoption

• US – 3.0% CAGR – Focused adoption in aerospace and heavy machinery sectors

• Germany – 3.0% CAGR – Precision engineering and high-quality manufacturing standards

Regional insights

• China remains the primary market due to strong automotive production, electronics manufacturing, and industrial machinery expansion. Investments in localized production facilities by top players reduce lead times and cost.

• Japan benefits from advanced automation and precision-driven manufacturing, demanding high-pressure and compact solutions.

• India is a high-growth opportunity, with OEMs increasingly integrating nitrogen gas springs into automotive and industrial lines.

• US and Germany see niche adoption for aerospace and heavy machinery, where high durability and predictable force are prioritized.

For access to full forecasts, regional breakouts, company share analysis, and emerging trend assessments, you can purchase the complete report here: Buy Full Report – https://www.futuremarketinsights.com/checkout/20533

What teams should do next

R&D

• Focus on high-pressure, compact designs for automotive and aerospace applications

• Expand calibration libraries for precise force control across diverse industries

• Innovate in lightweight, corrosion-resistant materials for extended service life

Marketing & Sales

• Highlight dyno-tested and field-proven performance in industrial stamping and automotive lines

• Develop bundled solutions for OEMs and integrator clients

• Promote creator and installer partnerships to build visibility and adoption

Regulatory & QA

• Ensure compliance with noise, emissions, and industrial safety standards

• Maintain complete fitment documentation for repeatable deployment

• Provide clear warranty terms for high-pressure applications

Sourcing & Operations

• Implement dual-sourcing strategies for high-pressure alloys and components

• Pre-kit key product lines for automotive and industrial clients

• Regionalize production to meet fast-growing industrial hubs and reduce logistics costs

Key performance indicators

• Pressure capacity – High-pressure springs dominate due to industrial and automotive requirements

• Durability and lifespan – Long-lasting springs improve reliability in heavy-duty applications

• Customization – Tailored solutions increase loyalty and industrial adoption

• Local manufacturing – Reduces lead times and lowers delivery costs

Three quick plays this quarter

• Pilot high-pressure springs in automotive stamping facilities

• Conduct precision force demonstrations in aerospace and heavy machinery sectors

• Launch marketing campaigns targeting electronics and medical device OEMs

The take

China’s nitrogen gas springs market is on a sustained growth trajectory, driven by repeatable performance, durability, and industrial precision. Manufacturers and integrators that deliver high-pressure, compact, and customizable solutions while ensuring field reliability will dominate the sector. Across automotive, aerospace, electronics, and machinery applications, predictable output, low-maintenance design, and compliance with industrial standards are driving adoption and loyalty. Teams aligning R&D, marketing, QA, and operations to these growth vectors are positioned to capitalize on both existing demand and emerging opportunities across multiple high-value sectors.

Manufacturers investing in localized production, customized solutions, and precision calibration libraries are likely to see accelerated adoption, repeat business, and enhanced reputation as a trusted industrial partner. Nitrogen gas springs are no longer optional components but critical enablers of efficiency, precision, and reliability in modern manufacturing operations.

Similar Industry Reports

China Autonomous Crane Market

https://www.futuremarketinsights.com/reports/china-autonomous-crane-market

China Elevator Ropes Market

https://www.futuremarketinsights.com/reports/china-elevator-ropes-market

China Packaging Primers Market

https://www.futuremarketinsights.com/reports/china-packaging-primers-market

China Spinal Fusion Market

https://www.futuremarketinsights.com/reports/spinal-fusion-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why Choose FMI: Empowering Decisions that Drive Real-World Outcomes: https://www.futuremarketinsights.com/why-fmi

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.